Product Features

Structure type: It is a vertical centrifugal slurry pump

Transport materials: It’s suitable for conveying abrasive or corrosive slag slurry.

Applications:It is widely used in metallurgical, mining, coal, electric power, building materials, chemical and other industrial departments. The submerged slurry pump is divided into ZV type and ZVR type, with the same structure.

ZV type submerged slurry pump, the flow passage parts and shaft are made of wear-resistant metal, which is suitable for conveying abrasive slurry.

The letter L contained in the model is the extended shaft series submerged slurry pump, which can be applied to the working condition under deep water.

Transmission mode: Direct drive or belt drive can be adopted, and the sheaves can be easily replaced.

Installation and usage: It can work in the pool or pit without any shaft seal or shaft seal water.

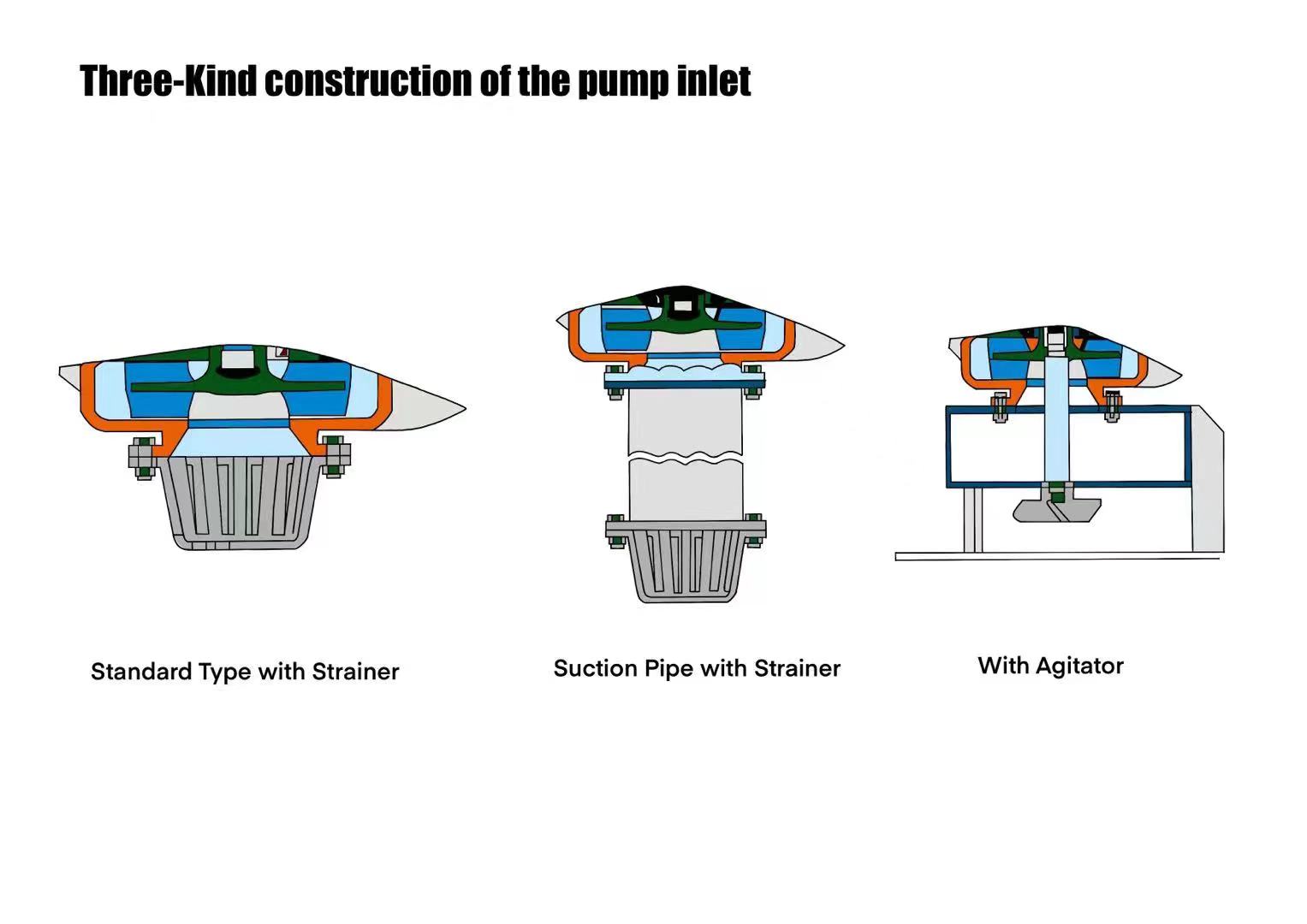

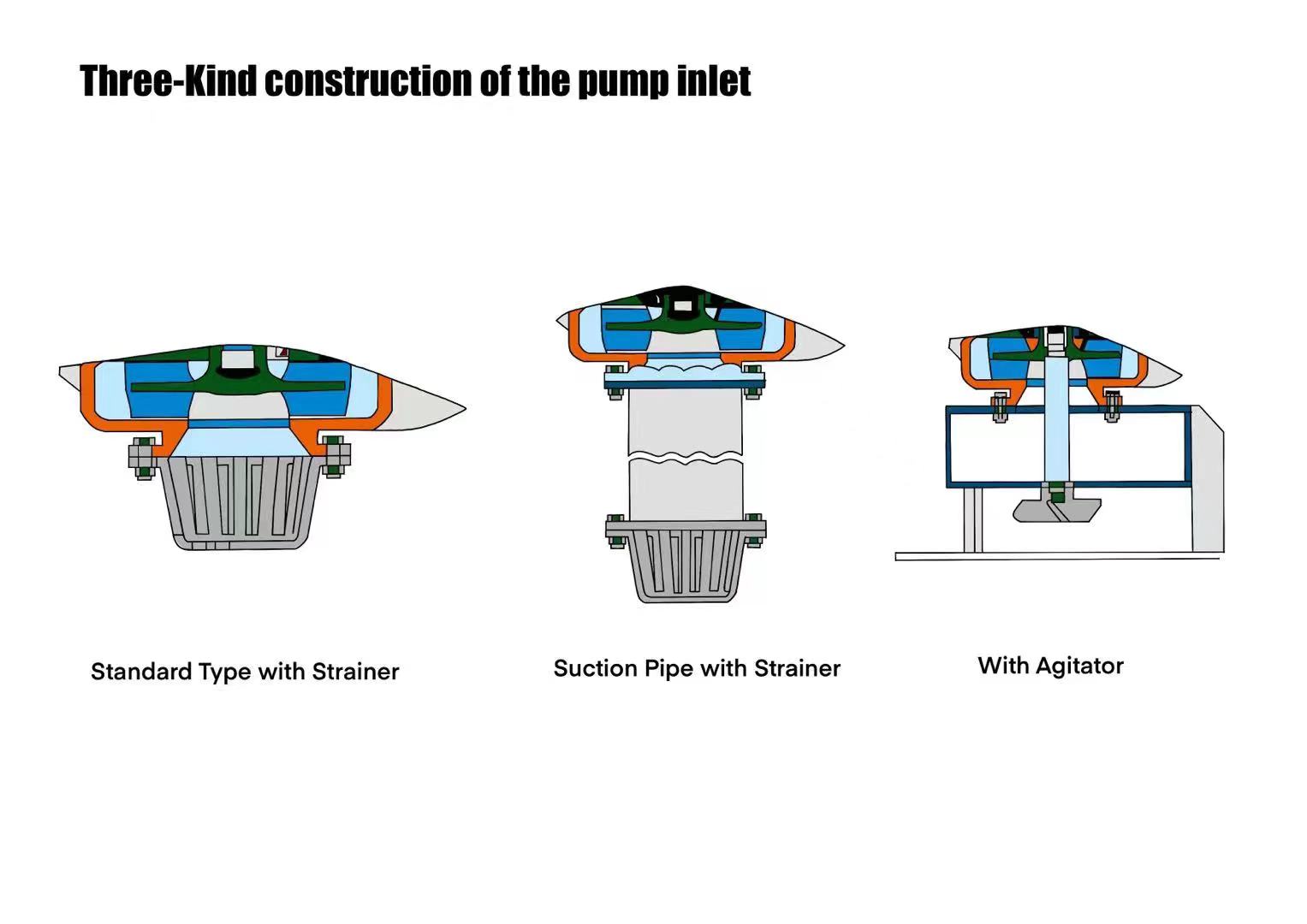

Anatomical drawing:

Material Construction:

| Description | Standard Material | Optional Material |

| Impeller | A05 | A33, A49 |

| Casing | A05 | A33, A49 |

| Back Liner | A05 | A33, A49 |

| Shaft | Carbon Steel | SUS304, SUS316(L) |

| Discharge Pipe | 20# Mild Steel | SUS304, SUS316(L) |

| Column | 20# Mild Steel | SUS304, SUS316(L) |

The ZV heavy duty cantilever sump pump is designed for applications requiring greater reliability and durability than conventional vertical process pumps can offer.

The heavy duty catilever design makes the ZV sump pump ideally suited for heavy continous handling of abrasive liquids and slurries whilst submerged in sumps or pits.

The rugged ZV heavy duty sump pumps are available in a wide range of popular sizes to suit most pumping applications.

ZV extended shaft submerged slurry pump is a vertical centrifugal slurry pump. It is a new generation of high-efficiency, wear-resistant and energy-saving vertical slurry pump developed by our factory. This series adopts the internationally advanced solid-liquid two-phase flow theory and is designed according to the principle of minimum loss. The geometry of its flow passage parts conforms to the flow state of medium, reducing the local and along-the-way hydraulic losses caused by eddy current and impact, so as to reduce the wear of flow passage parts and improve the hydraulic efficiency, The running noise and vibration are reduced. The flow passage parts of this series of pumps are made of high chromium alloy. This series of slurry pumps are innovative in hydraulic design and structural design. The flow passage parts are made of self-developed abrasion resistant high chromium wear-resistant alloy, which has the remarkable characteristics of high efficiency, energy saving, long service life, light weight, reasonable structure, reliable operation, low vibration, low noise and convenient maintenance.

Thousands of these pumps are proving their reliability and efficiency worldwide in:

Minerals Processing

Coal Preparation

Chemical Processing

Effluent Handling

Sand and Gravel

and almost every other tank, pit or hole-in-the-ground slurry handling situation.