Product Features

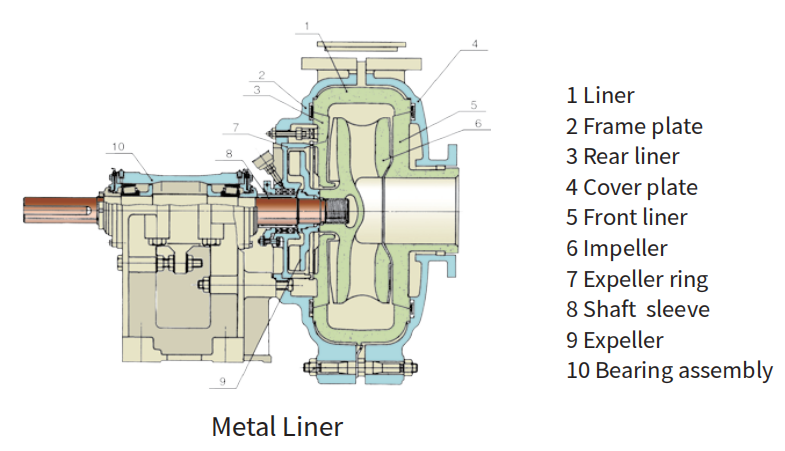

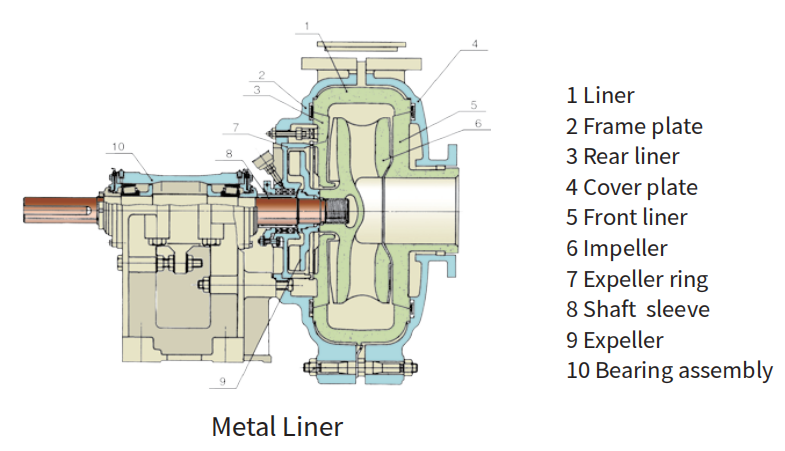

Structure type: Type ZHH slurry pumps are double shell cantilever horizontal centrifugal pump.

Transport materials: They are designed for conveying strong corrosion and high concentration slag slurry.

Applications: They are widely used in metallurgy, mining, petroleum, chemical industry, coal, electric power, transportation, river dredging, building materials and municipal engineering etc.

Lining materials: Wear resistant metal lining.

Characteristics:

Type ZHH, also called High Head heavy-duty slurry pump.Because this type of pump has thick wear parts and heavy base,Therefore, it is suitable for conveying strong abrasion, high concentration slag slurry or low concentration high lift slag slurry,Within the maximum allowable working pressure range of the pump, it can be used in series.Type ZHH pump is suitable for conveying low concentration high lift slag slurry or high concentration low abrasion high lift slag slurry.The above types of pumps can also be used for slag slurry with certain abrasiveness.

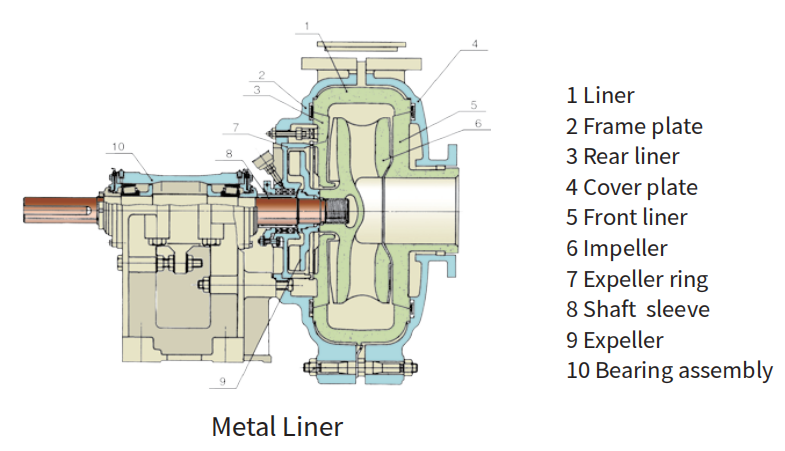

Construction Design:

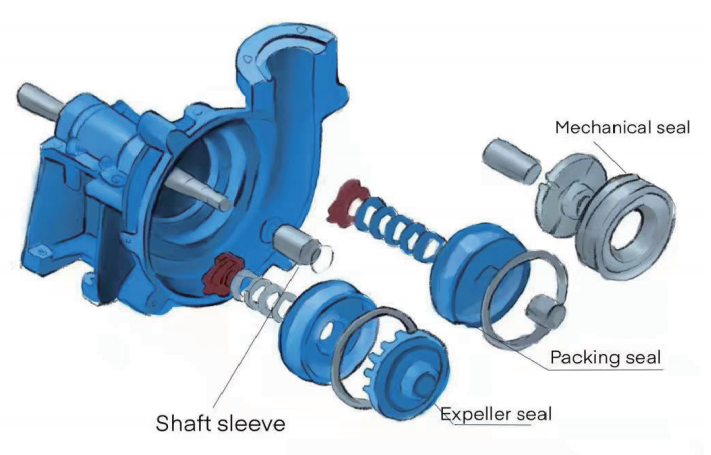

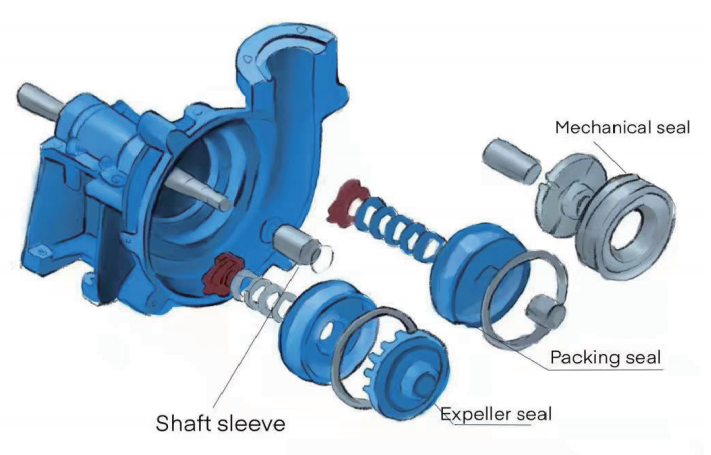

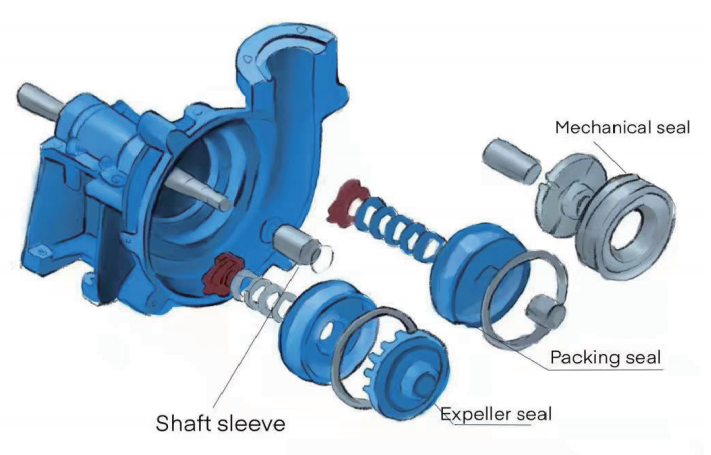

Shaft Seal Module Design:

Packing Seal,Expeller Seal,Mechanical Seal

Packing Seal

It is a common sealing system which is suitable for various conditions. It can be used in the corrosive or high temperature conditions by using PTFE (Teflon)packing, graphite packing or other special packing materials. It also can be used in the strong abrasive or corrosive conditions by using spray-ceramic shaft sleeve. It needs low flow or full flow flush device.

Expeller Seal

It is using the pressure between the impeller and the expeller to seal, and using the packing or lip-sealing ring for shut down seal. It doesn’t need sealing water.

Mechanical Seal

It is the world's most advanced sealing technology without sealing leakage. Packaged structure, easy to install and replace, by using the different structural forms, it can adapt to different working conditions. The friction deputy material is made of high hardness ceramic, silicon carbide and cemented carbide materials, it has high wear resistance and shock resistance, which can ensure good sealing effect under all kinds of bad working conditions.

Eight exit directions:

The outlet position of the pump can be spaced at 45 ℃ as required, It can be rotated at eight different angles to install and use. This type of pump can also be used in series.

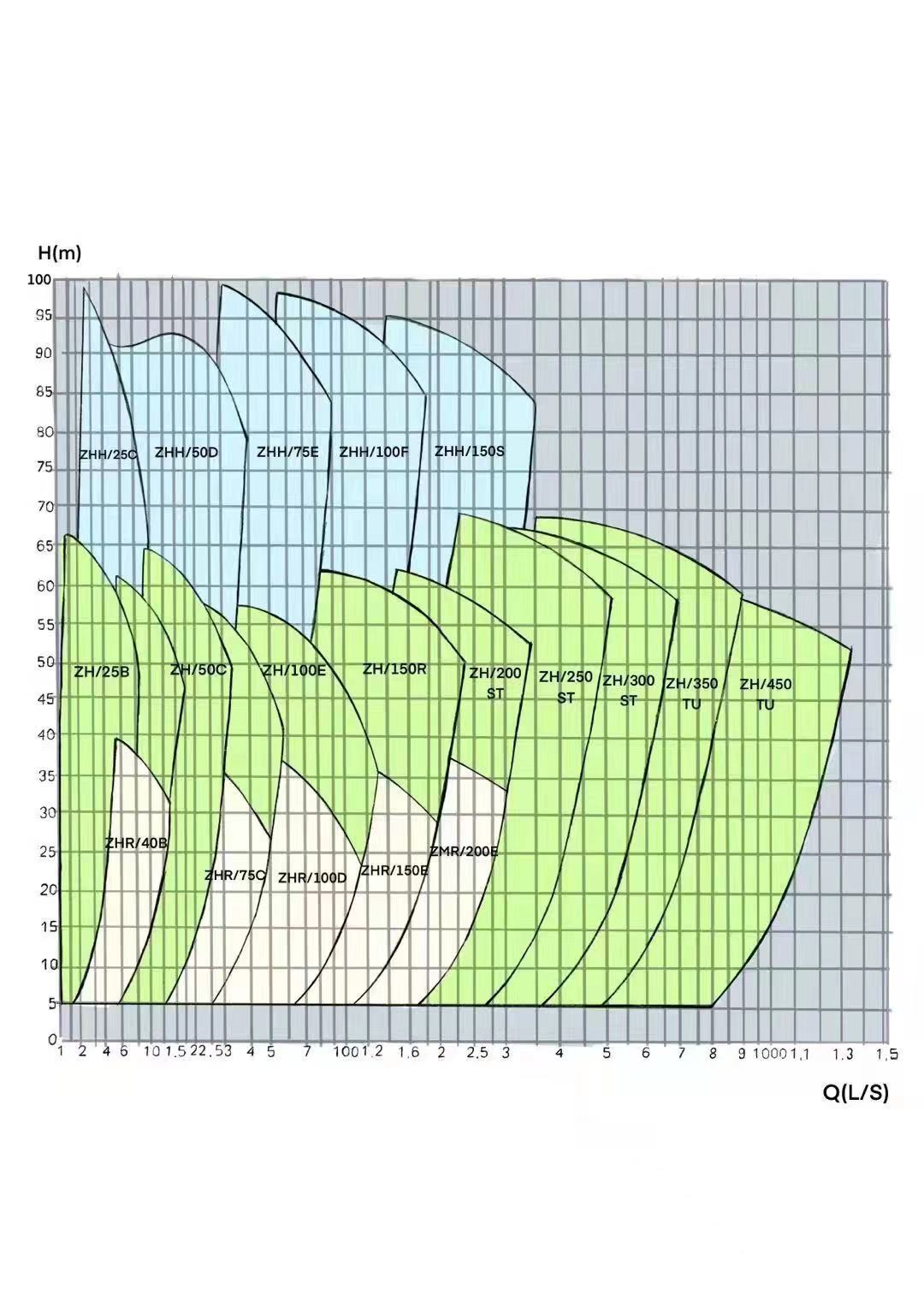

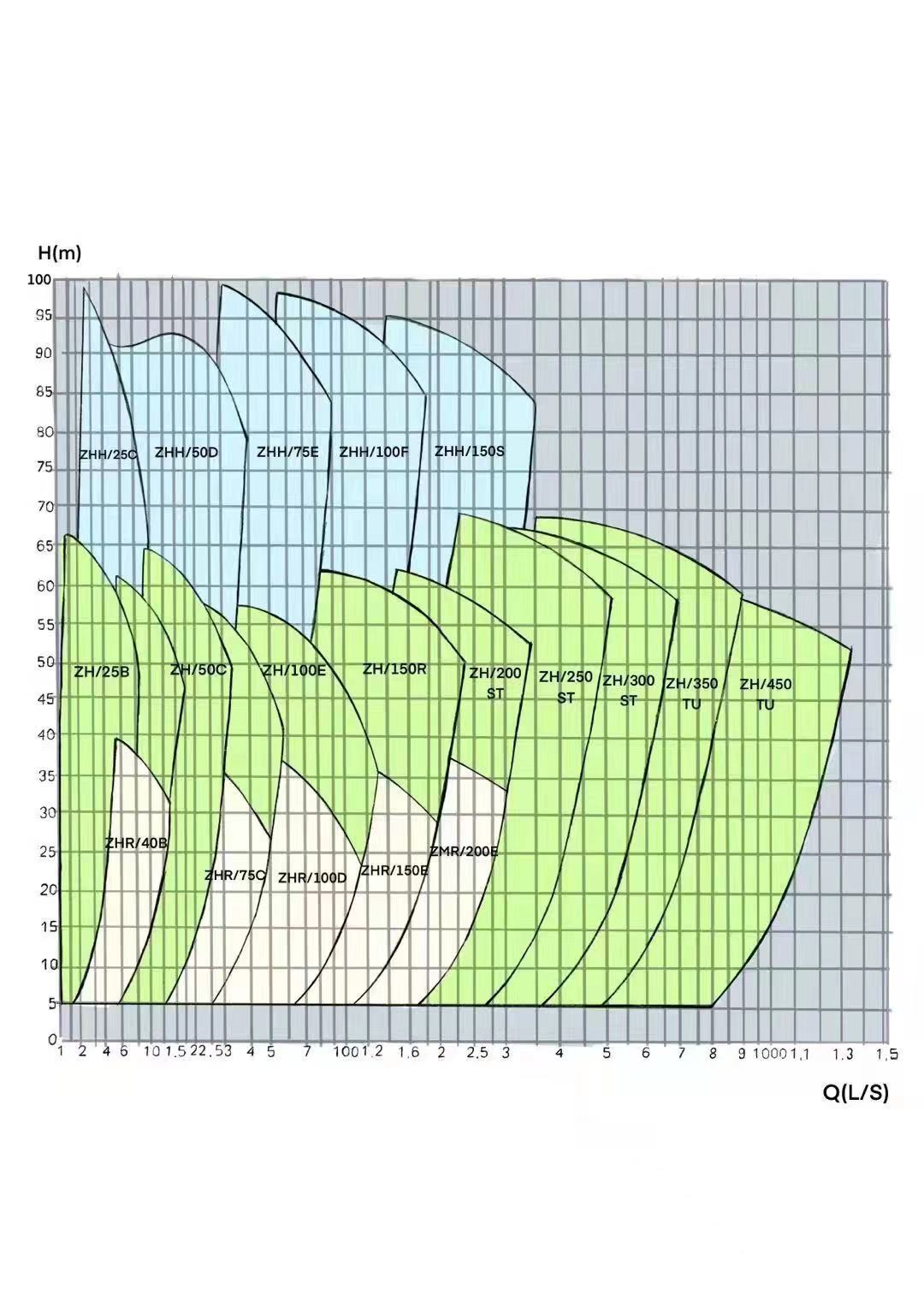

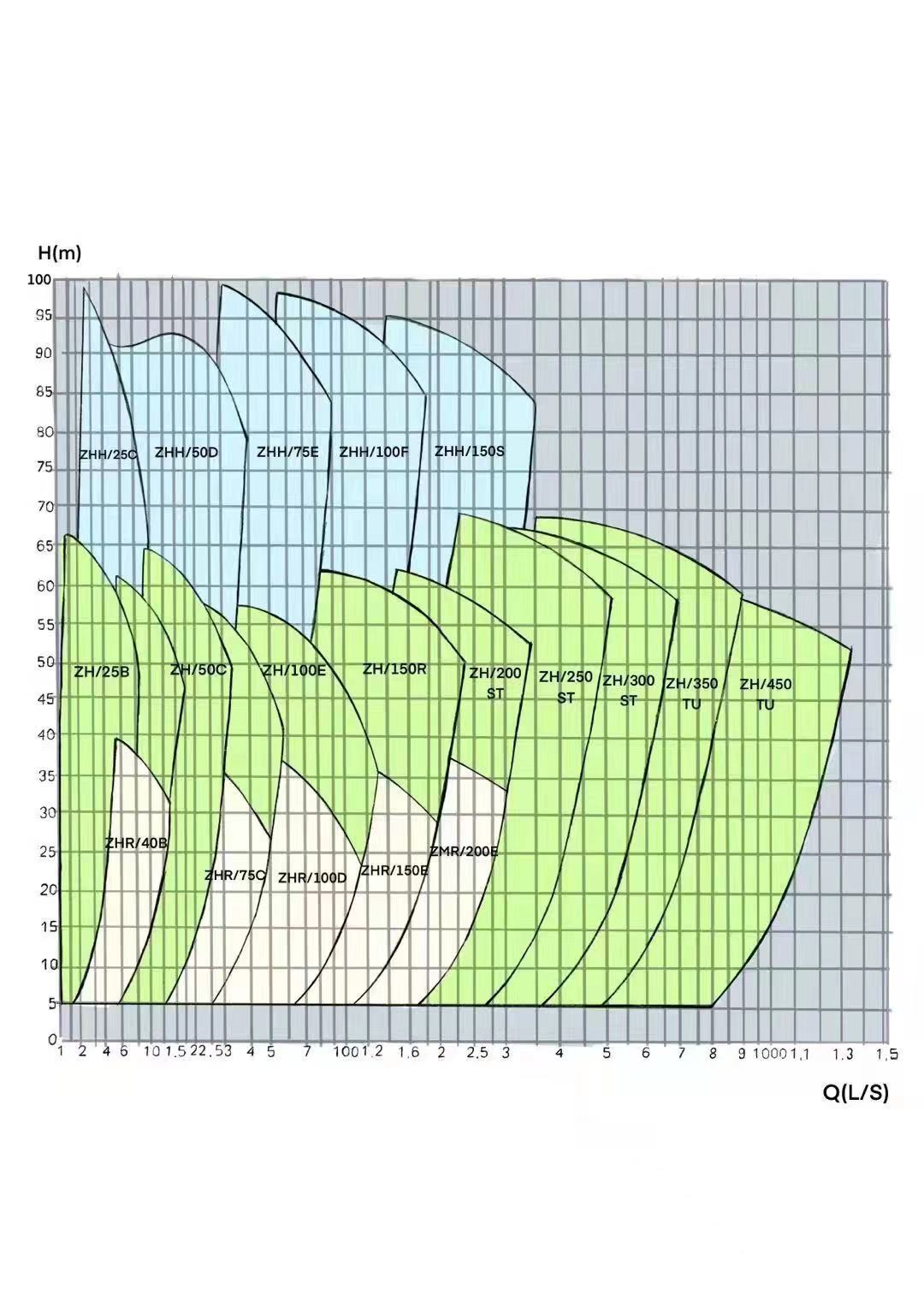

Model selection chart

Applications:

Ball/rod mill discharge

Coarse sand/tailings

Minerals concentrate

Heavy media

Bottom/fly ash, lime grinding

Features and Advantages:

▶Heavy duty construction with through-bolt design provides ease of maintenance and minimal downtime

▶Large, open internal passages designed to reduce internal velocities, maximize wear life and lower operating costs

▶Minimal shaft/impeller overhang reduces shaft deflection and increase packing life

▶Effective expeller prolongs packing life while reducing or eliminating flush water requirement.

Product Features

Structure type: Type ZHH slurry pumps are double shell cantilever horizontal centrifugal pump.

Transport materials: They are designed for conveying strong corrosion and high concentration slag slurry.

Applications: They are widely used in metallurgy, mining, petroleum, chemical industry, coal, electric power, transportation, river dredging, building materials and municipal engineering etc.

Lining materials: Wear resistant metal lining.

Characteristics:

Type ZHH, also called High Head heavy-duty slurry pump.Because this type of pump has thick wear parts and heavy base,Therefore, it is suitable for conveying strong abrasion, high concentration slag slurry or low concentration high lift slag slurry,Within the maximum allowable working pressure range of the pump, it can be used in series.Type ZHH pump is suitable for conveying low concentration high lift slag slurry or high concentration low abrasion high lift slag slurry.The above types of pumps can also be used for slag slurry with certain abrasiveness.

Construction Design:

Shaft Seal Module Design:

Packing Seal,Expeller Seal,Mechanical Seal

Packing Seal

It is a common sealing system which is suitable for various conditions. It can be used in the corrosive or high temperature conditions by using PTFE (Teflon)packing, graphite packing or other special packing materials. It also can be used in the strong abrasive or corrosive conditions by using spray-ceramic shaft sleeve. It needs low flow or full flow flush device.

Expeller Seal

It is using the pressure between the impeller and the expeller to seal, and using the packing or lip-sealing ring for shut down seal. It doesn’t need sealing water.

Mechanical Seal

It is the world's most advanced sealing technology without sealing leakage. Packaged structure, easy to install and replace, by using the different structural forms, it can adapt to different working conditions. The friction deputy material is made of high hardness ceramic, silicon carbide and cemented carbide materials, it has high wear resistance and shock resistance, which can ensure good sealing effect under all kinds of bad working conditions.

Eight exit directions:

The outlet position of the pump can be spaced at 45 ℃ as required, It can be rotated at eight different angles to install and use. This type of pump can also be used in series.

Model selection chart