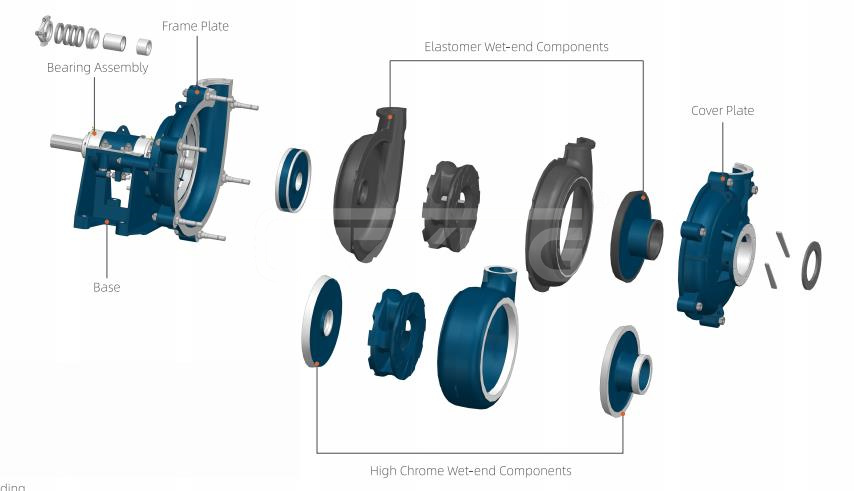

CNZking® Slurry Pump DESIGN FEATURES:

IMPELLER - Large flow passages boost the pumps ability to pass solids while a large diameter allows low-speedoperation therefore reducing wear.

CASING - Volute design to pass large solids with minimal turbulence and re-circulation. Extra thick wall sectionsat wear points for extended life.

STUFFING BOX - Easily accessible, the stuffing box comes standard in a weep type arrangement as shown. A flushtype design (lantern ring on the casing side of all packing rings)

SUCTION COVER & LINER - Liner protects the suction cover form abrasive wear, reducing replacement costs.

Easily removable providing access to the impeller.

HEAVY DUTY SHAFT - Rugged design for handling loads and vibration. Threaded to the impeller, the shaft end is

protected from abrasion.

EXTERNAL IMPELLER ADJUSTMENT-Maintains original performance by adjustable screws without disassembleof your pump.

HEAVY DUTY BEARINGS -Bearings are sized for extended life. A split housing simplifies periodic inspection. The deflector protects bearings for dirt and moisture.

Industry Applications:

Fracing slurry

Pot ash tailings

Coal slurry

Cement slurry

Bauxite slurry

Sand slurry

Red mud

Fly ash

Bottom ash

Kaolin clay

Phosphate ore

Mud & silt

Dredge tailings

Mill scale

Alumina hydrate

lron ore

Slag

Chalk slurry

Lime slurry

Clarifier sludge

Coal refuse

Textile wastes

Copper ore slurry

Back to list

Back to list