Slurry Pumps

For the transportation of liquids that have a high level of contamination, it is advisable to buy a slurry pump - a specially adapted equipment of the centrifugal principle of operation. Such units can effectively perform pumping work:

- sand from the bottom of rivers for construction and industrial use;

- rainwater and supply water from mines and quarries;

- water contaminated with small stones, industrial waste and other technological impurities;

- impurities of alumina production;

- high concentration flushing solutions;

- household sewage and other contaminated liquids.

Design features

Slurry pumping equipment is equipped with the following structural units and mechanisms:

- body;

- impeller equipped with rotating blades;

- electric motor;

- powerful rotor with an increased diameter;

- armored disc;

- a stator, in which the wall thickness is thinner than in pumps of other liquid designs;

- additional cooling system (in vertical and horizontal modifications) to prevent overheating.

The main working units are made of heavy metals with a chromium content of up to 28%. A rubber coating can be applied on top, which increases the life of the model.

Slurry Pump Classification

Depending on the design, slurry pumps for pumping dirty water are of horizontal, vertical and submersible type.

Horizontal modifications are installed outside the slurry tank. These are dry-type devices designed to capture solid particles in a mixture of a transported liquid. It is rational to use them for pumping hydraulic mixture, with the presence of solid ingredients up to 20 mm and with temperatures up to +50°C. Contaminated liquids with a density of 2500 kg/m³ are optimally captured through the inlet. Horizontal pumps are available in a wide range of capacities and pressures.

Vertical modifications pump liquids, in the total volume of which there is no more than 20% of contaminants. Limiting density of capturing liquids – no more than 1300 kg/m³. Such devices are also designed for dry installation, but unlike horizontal models, they exclude the formation of air pockets, which can cause a temporary stop in work.

Submersible modifications are used in places where direct contact with the pumped liquid is required, it is necessary to regulate the area and spatial positions of movement. During their work, a cable is often used to ensure the movement of the pump to the place of pumping. With the help of a cable, the pump is gradually immersed in the sludge as it is removed to the required depth. Thick slurry naturally enters the impeller of the unit and is pumped further. Descent level adjustment is determined visually. Due to the fact that the unit is immersed in liquid, noiseless operation is ensured.

Submersible pumps are designed to operate in difficult conditions. They are made of special wear-resistant alloys that are resistant to abrasive influences. Compared with horizontal and vertical models, the submersible slurry pump has an effective degree of protection against overheating, thanks to passive automatic cooling by the working mixture. We have pumps useful for meticulous cleaning of sewers, silted rivers, lakes, drain pits and other contaminated containers and reservoirs. They help to solve a wide range of tasks for pumping contaminated water in the construction and industrial industries, utilities, as well as for fire fighting.

World manufacturers

Currently, there are more than 100 global manufacturers of slurry equipment. We represent only the most famous brands.

Manufacturer Eisele

German manufacturer of pumping equipment. We are the representative of this company in the Republic of Belarus. We offer pumps for use in the following sectors: Agriculture / Wastewater treatment plants / Biogas plants / Dirt pits / Slaughterhouses / Gravel plants / Pig farms - liquid feeding systems / Paint production - mixing and waste pumping / Ground water pumping / Ceramic production. Eisele has been designing and manufacturing rotary lobe pumps since 1983. All pumps are tested under real conditions in agricultural and industrial facilities.

Manufacturer Warman® QCL

Warman® Q Series Axial Pumps - These models guarantee low maintenance costs and high quality from a company with a proven track record in the world. Warman® are a highly reliable and energy efficient pump choice for the continuous circulation of abrasive and corrosive fluids. Models will provide low operating costs and high quality from a company with proven global experience.

Manufacturer NETZSCH Pumps & Systems

It has more than 2,000 employees in five development and production centers around the world, as well as 35 trading companies, partners in Japan. More than 200 NETZSCH representatives working for you all over the world. The company produces progressive cavity slurry pumps. NEMO® is of particular interest where pumps are installed in high wear conditions requiring more maintenance and repair work.

Manufacturer ARO, Ingersoll Rand

Produces pneumatic centrifugal pumps ARO provide effective performance up to 230 g/min (870.5 l/min). Compact in size, these pumps are suitable for pumping water from trenches, wells, holds, pits or other bodies of water.

https://www.ingersollrand.com/

Manufacturer Albin Pump

This manufacturer produces reliable pumps for pumping high viscosity sludge, clay, large particles, lead sulfate, pyrite, SABX, cyanide, various acids. All slurry pumps are designed and manufactured in-house in France. Albin Pump is part of Ingersoll Rand, which boasts a wide range of fluid handling products and brands such as ARO, Milton Roy, Thomas, Dosatron, Haskel and more. Ingersoll Rand Inc.

Manufacturer SolidPump

The Swiss company SolidPump specializes in submersible slurry and sand, submersible drainage and compact portable drainage pumps. Construction drainage, bentonite pumping, mine dewatering, light sand dredging, sump, pond and river cleaning, sludge/slurry pumping are just a few of the applications where Solidpump products can benefit.

Manufacturer IBO

IBO produces deep, surface, fecal pumps and pumping stations. Deep wells of this company are chosen by drilling companies for pumping new wells.

Manufacturer Grundfos

The Danish concern Grundfos represents a wide range of pumps for domestic and industrial use - from self-priming, cantilever, multistage with liquid filtration to pumps for cleaning wells from silt.

Manufacturer SAER

The Italian manufacturer offers models for pumping domestic and industrial waste water, viscous and corrosive liquids, liquids with fibrous and solid substances, liquid agricultural sludge, dirty and clay water.

www.saerelettropompe.com

Produced by Emile Egger & Cie SA

The Swiss family company Emile Egger & Cie SA specializes in the design and manufacture of high quality centrifugal pumps for sensitive fluids with a high solids content. The company markets the ideal pump for the economical transport of wastewater and liquids with a high content of solids, fibrous and gases. The catalog presents pumping units for pumping raw sewage and liquids with a high content of fibers with high hydraulic efficiency.

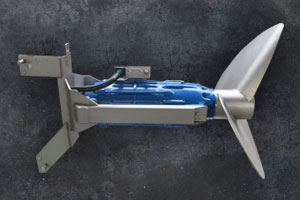

Manufacturer DRAGFLOW

The company can order hydraulic pumps for dredging, submersible hydraulic pumps with agitator. Their slurry pumps are particularly suitable for dredging with heavy or abrasive mixtures. Started in the 80s as a manufacturer of heavy duty submersible pumps.

Back to list

Back to list