For settling slurries, the velocity in the pipework is the key design criteria.

Perry’s Chemical Engineers’ Handbook

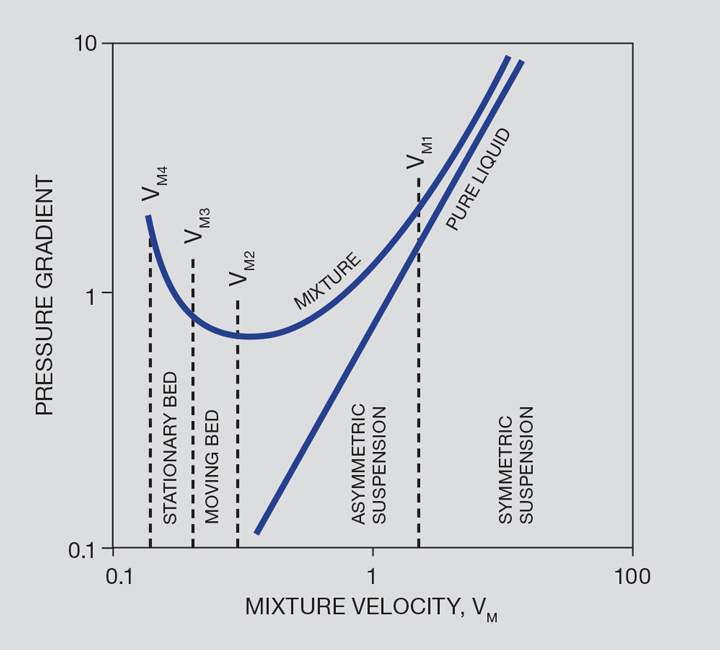

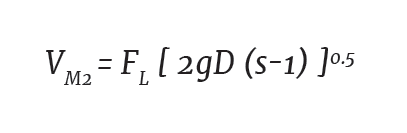

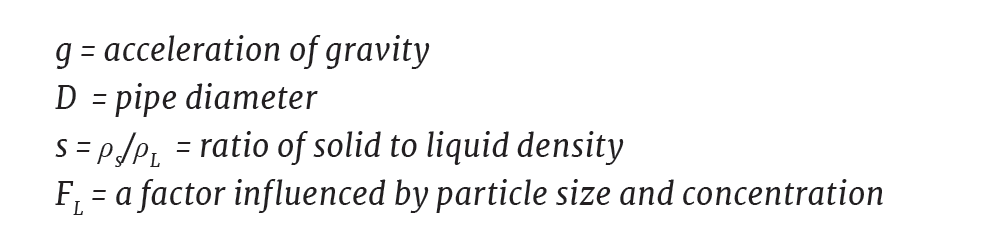

Figure 1, an extract from Perry’s Chemical Engineers’ Handbook, depicts the relationship between the pressure drop and the slurry’s velocity compared to a pure liquid in horizontal pipework. The important point to note is that the horizontal pipe velocity should be above the point labelled Vm2 (minimum transport velocity). This is the point at which the solids are fully suspended. This is determined using the Durand equation3.

where:

Once the minimum transport velocity is calculated, it is common to add a safety factor, but care is needed. If the velocity is too high, the required pressure drop and the subsequent work required by the pump can increase significantly. For vertical flow, a good starting velocity can be taken as twice the solid’s settling velocity. The main aim is to stop the solids from dropping out. Velocities in the range of 1-3 m/s is a useful rule of thumb.3

The pressure drop for settling slurries can now be determined at the calculated velocity assuming pseudo-homogeneous behaviour, using the slurry’s density and the carrier fluid’s viscosity in established pressure drop calculation and applying a correction factor. A correction factor of 25% is suggested in Perry’s Chemical Engineers’ Handbook3.

Note that the above is for solids heavier than the carrier fluid. Depending on the solid particle size, at particular concentrations the particles begin to interact with each other and can start to affect the slurry’s viscosity. This is discussed further with calculations provided in the Processing of Solid-Liquid Suspensions, Chapter 112. Appendix 3, Warman Slurry Pumping Handbook4, also has useful calculations and correlations for water-based slurries.

For non-settling slurries, the resultant slurry typically displays non-Newtonian behaviour, and its rheology and behaviour must be determined empirically to ascertain the work required by the pump. The pressure drop for these can then be calculated using established pressure drop calculations depending on the slurry viscosity and density calculated.

Other things to consider before moving onto pump selection are:

- slip conditions – when the solid and carrier velocities differ significantly;

- pipe size – ensure the pipe ID is considerably bigger than maximum particle size (6-10x is recommended2);

- piping design (using recirculation loops to ensure the slurry is constantly moving; using falls, so the slurry drains to a safe point; using long radius bends; installing rodding or flushing points; minimising bends; minimising dead legs; minimising suction pipework);

- static head requirements; and

- available NPSH.

The solid particle will play a crucial part in selecting the material of the wetted parts. The following, amongst other things, should be considered:

- are the solids hard or soft? ie are they abrasive?

- will pumping the slurry cause erosion?

- are the solids corrosive? This applies to the carrier fluid.

Pump types

As with many pump duties, both rotary and positive-displacement pumps can be utilised. The following are some of the aspects to consider when selecting the type of pump for your slurry. However, always check with specialist pump suppliers before making a final decision.

Centrifugal pumps

The most common pumps generally in use are centrifugal pumps. When specifying this type of pump, as a minimum, the following must be considered:

- Impeller type – A recessed impeller type can be used, the design minimises contact between the particles and the impeller thereby minimising wear on the impeller whilst being gentle on the particles. Open impeller types can be used, as they are generally easier to clean and maintain. Closed impellers are often regarded as having the best efficiency but can be difficult to clean. The thickness should have suitable wear allowance. You should also consider any impact caused by the required impeller speed.

- Casing type – Metal casings can be used. These may be lined with rubber for added protection or as a sacrificial wear part. Split casings can also be considered, but these can be expensive. The thickness should have suitable wear allowance.

- Clearances – Slurry centrifugal pumps should have larger clearances than pure liquid pumps, to allow solids to pass through but also to reduce the velocity within the pump, thereby minimising wear.

These are just some of the things to consider when selecting a centrifugal pump for a slurry duty. In direct liaison with a pump vendor, the designer must choose the best options for their system. They should also consider any impact on the shaft and seals, and ensure there will be no issues with cavitation.

Back to list

Back to list