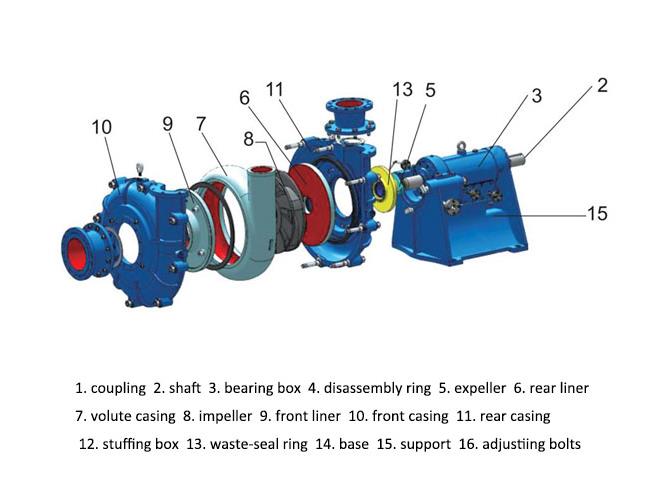

At ZKING we understand the importance of easy and predictable maintenance, and so the ZJ pump range was designed with these thoughts in mind. Alignment features throughout ensure all components are in exact alignment along the pump shaft from drive coupling to the throatbush.

Large robust bearings that can run at high speed.

Rigid overhung shaft with short overhang and large diameter shaft for minimum deflection, and improved reliability of mechanical seals.

Rough castings will be transferred into the machining shop after they are inspected qualified. At Shijiazhuang Minerals Equipment Co. Ltd, you`ll find more than 20 sets of machining equipments including vertical lathe, round lathe, boring and milling lathe, CNC lathe, radial drilling machine and cylindrical grinder, which makes it possible to machine spare parts with a maximum diameter of 2.5 meters. Our machining team consists of the best engineers in the slurry pump business and we guarantee the machining accuracy of the products. The finished spare parts cannot be warehoused until they are inspected qualified and perfect.

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Typical Applications:

Bottom/Fly Ash

Coal Washing

Power Plants

Potash Fertilizer Plant

Iron Ore Dressing Plant

Gold Mine Concentration Plant

Specifications:

| Model | 200ZJ |

| Capacity | 199-976m3/h |

| TDH | 13-133.7m |

| Max. Allowable Motor Power | 185/250/315/355/560Kw |

| Speed | 490-980r/min |

| Max. Efficiency | 83.5% |

| Lubrication | Oil |

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Typical Applications:

Bottom/Fly Ash

Coal Washing

Power Plants

Potash Fertilizer Plant

Iron Ore Dressing Plant

Gold Mine Concentration Plant

Orders of ZJ Severe Duty Slurry Pumps:

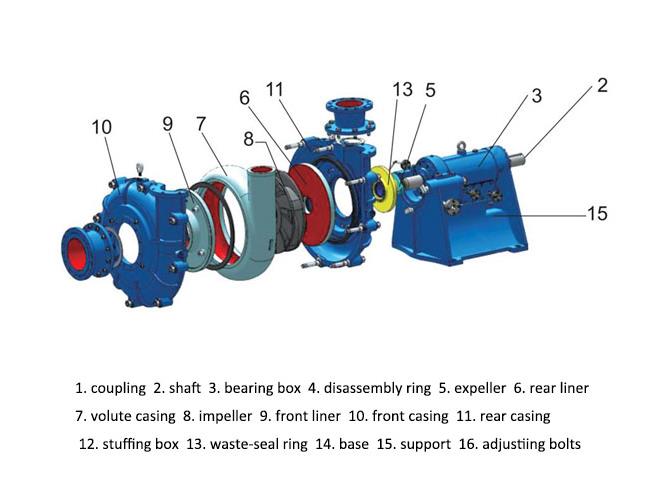

At ZKING we understand the importance of easy and predictable maintenance, and so the ZJ pump range was designed with these thoughts in mind. Alignment features throughout ensure all components are in exact alignment along the pump shaft from drive coupling to the throatbush.

Large robust bearings that can run at high speed.

Rigid overhung shaft with short overhang and large diameter shaft for minimum deflection, and improved reliability of mechanical seals.

Rough castings will be transferred into the machining shop after they are inspected qualified. At Shijiazhuang Zking Equipment Co. Ltd, you`ll find more than 20 sets of machining equipments including vertical lathe, round lathe, boring and milling lathe, CNC lathe, radial drilling machine and cylindrical grinder, which makes it possible to machine spare parts with a maximum diameter of 2.5 meters. Our machining team consists of the best engineers in the slurry pump business and we guarantee the machining accuracy of the products. The finished spare parts cannot be warehoused until they are inspected qualified and perfect.

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Typical Applications:

Bottom/Fly Ash

Coal Washing

Power Plants

Potash Fertilizer Plant

Iron Ore Dressing Plant

Gold Mine Concentration Plant

Orders of ZJ Severe Duty Slurry Pumps:

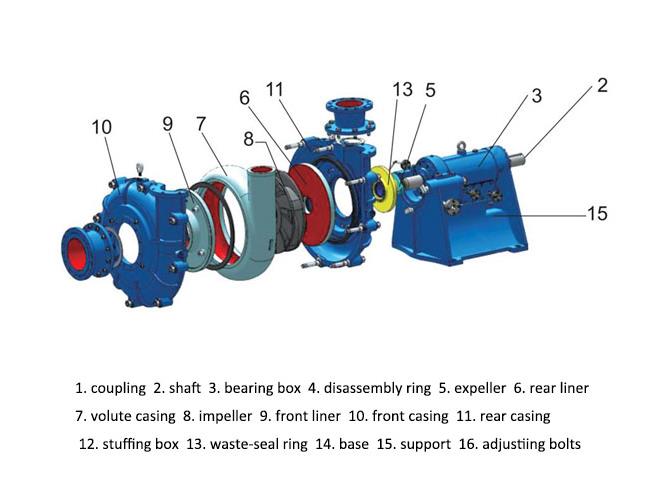

At ZKING we understand the importance of easy and predictable maintenance, and so the ZJ pump range was designed with these thoughts in mind. Alignment features throughout ensure all components are in exact alignment along the pump shaft from drive coupling to the throatbush.

Large robust bearings that can run at high speed.

Rigid overhung shaft with short overhang and large diameter shaft for minimum deflection, and improved reliability of mechanical seals.

Rough castings will be transferred into the machining shop after they are inspected qualified. At Shijiazhuang Minerals Equipment Co. Ltd, you`ll find more than 20 sets of machining equipments including vertical lathe, round lathe, boring and milling lathe, CNC lathe, radial drilling machine and cylindrical grinder, which makes it possible to machine spare parts with a maximum diameter of 2.5 meters. Our machining team consists of the best engineers in the slurry pump business and we guarantee the machining accuracy of the products. The finished spare parts cannot be warehoused until they are inspected qualified and perfect.

Standard Material of Wet-end Parts: Hi-Chrome Alloy A05

Typical Applications:

Bottom/Fly Ash

Coal Washing

Power Plants

Potash Fertilizer Plant

Iron Ore Dressing Plant

Gold Mine Concentration Plant